PRODUCTS

Biogas is produced during the biological breakdown of organic solids through anaerobic digestion. The gas generated through this process is an energy source that can be collected and utilized, or safely burned. Biogas is a highly moist mixture of gases consisting of approximately 55-70% methane (CH₄), 25-35% carbon dioxide (CO2) with trace amounts of nitrogen and hydrogen sulfide. When recovered, biogas may be used in a multitude of ways such as; running a boiler for heating an anaerobic digester or used to run an engine-generator to generate electricity.

Anaerobic digestion is one of the most effective methods of treating biosolids from municipal and industrial wastewater. It is an ideal method in meeting strict environmental regulations in highly urban areas. The anaerobic process occurs in closed vessels (digesters), covered ponds or lagoons. Soluble organics are converted to CH4 and CO2 in a two-step process.

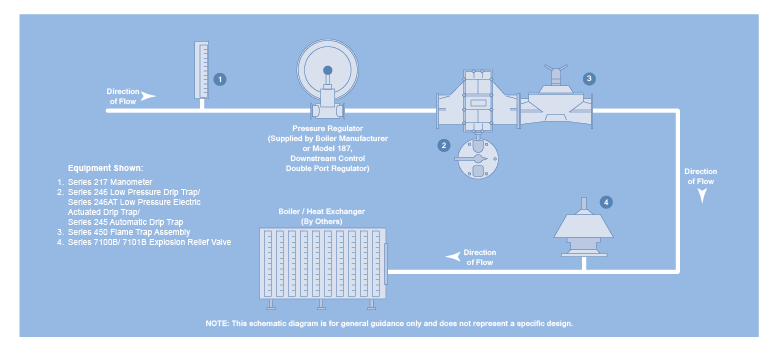

Biogas collection and utilization is an important part of the anaerobic digestion process. The low-heat-content gas is saturated and contains harmful elements that are also corrosive to piping and equipment. It is important to handle biogas properly to ensure a safe and protected environment. The key aspect of design is to recognize that biogas handling equipment operates as a system, making Varec Biogas the leading experts and your total solutions provider.

BURNERS AND FLARES

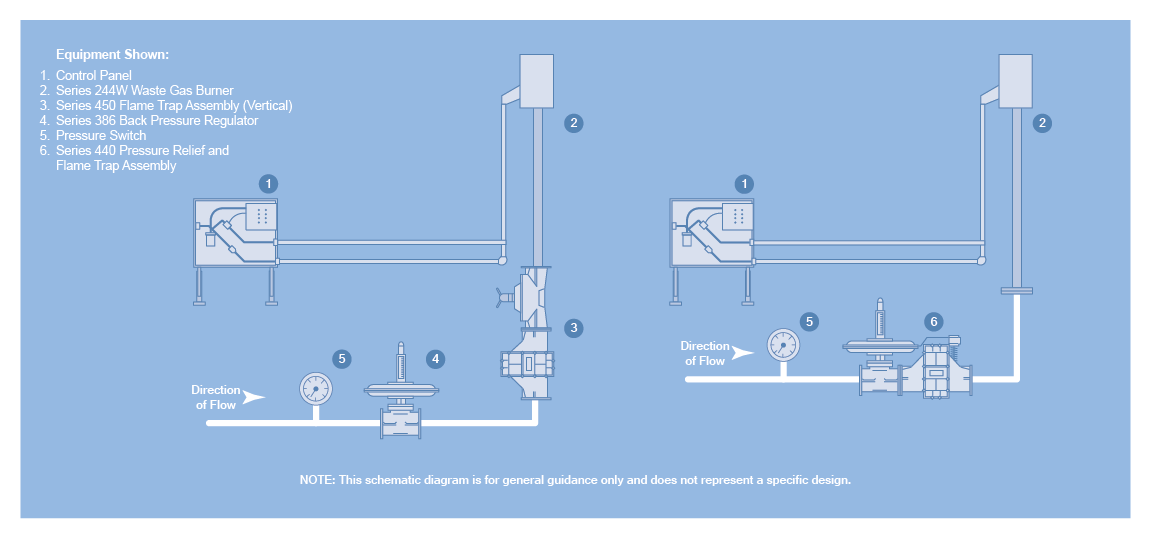

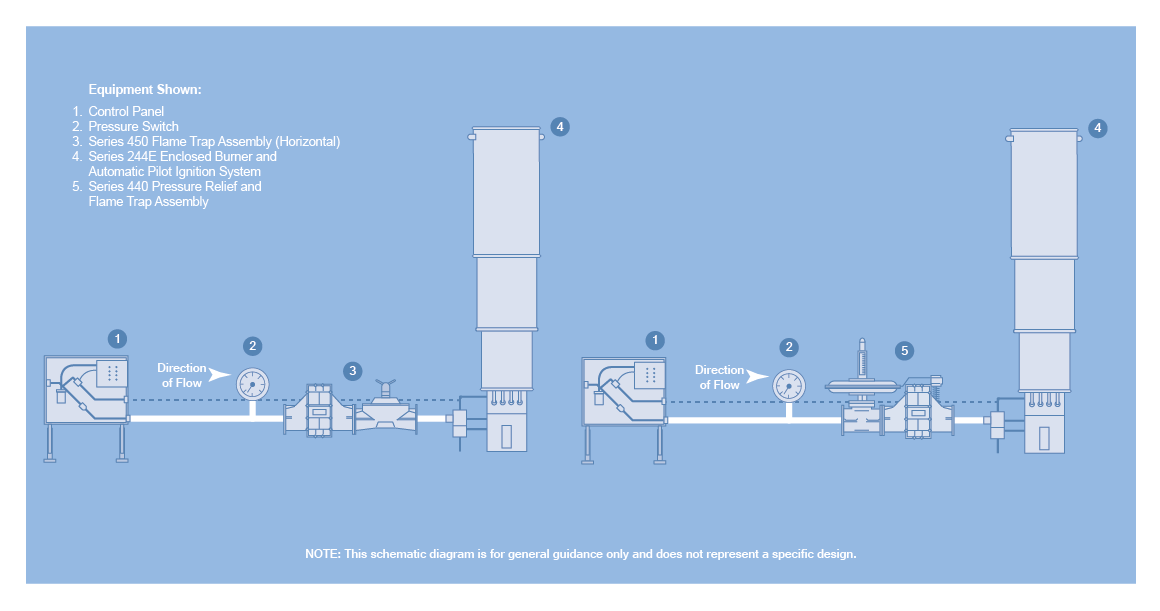

Excess biogas produced will need to be flared. Flares are sized for the maximum gas production of the plant and is used to not only flare excess gas produced but handle combustion of biogas in emergency situations. Varec Biogas pioneered flame-front technology for pilot ignition systems. To address air emission limits, Varec offers our patented Model 244E Enclosed flares that combust biogas and guarantees 99% destruction removal efficiency.

WASTE GAS BURNER

ENCLOSED FLARE

BURNERS AND FLARES PRODUCTS

DIGESTER COVER EQUIPMENT

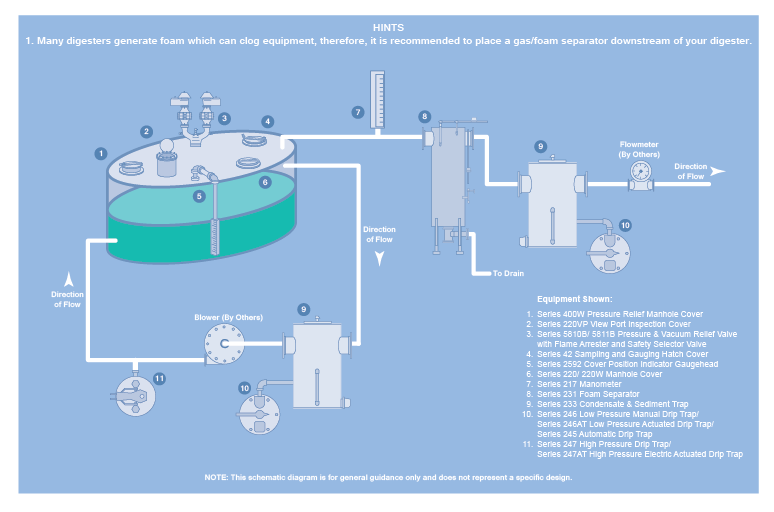

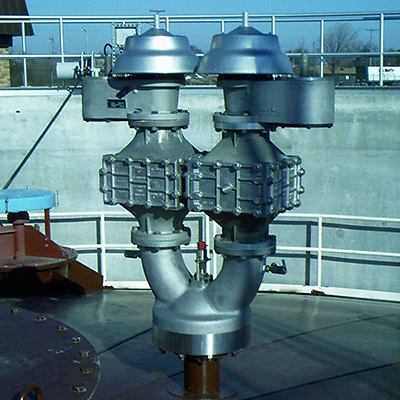

Varec Biogas supplies the safety equipment and accessories installed on digesters or on egg-shaped digesters. Safety equipment include redundant Pressure/Vacuum Relief Valve and Flame Arresters and Emergency pressure relief manhole covers. A Safety selector valve is used to allow switch-over of the redundant pressure relief system. Access hatches and sludge sampling hatch are required accessories. For floating steel covers, Varec Biogas offers mechanical position indicators with current output transmitters to monitor cover travel. Pressure relief systems are also required on intake lines of membrane gas holders.

DIGESTER COVER EQUIPMENT AND ACCESSORIES

DIGESTER COVER EQUIPMENT - VALVES

DIGESTER COVER EQUIPMENT - COVERS

DIGESTER COVER EQUIPMENT - ACCESSORIES

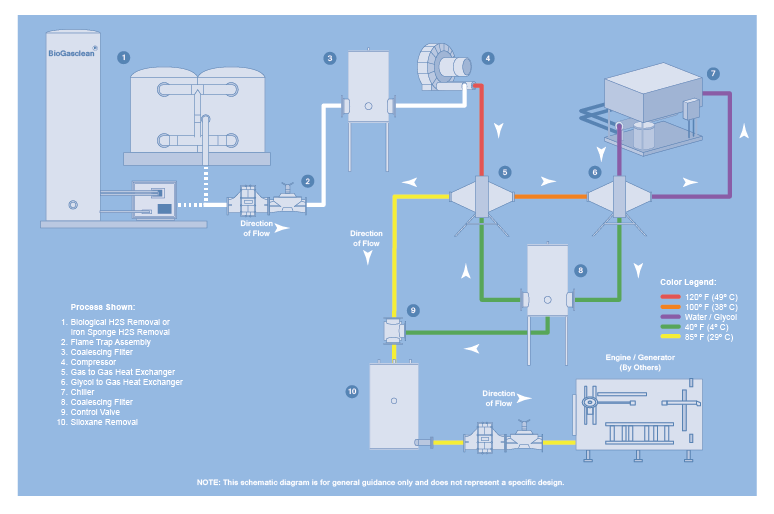

DIGESTER GAS CLEANING/ DRYING EQUIPMENT

Varec Biogas offers a complete system that will remove moisture, H2S and siloxane in the gas. Moisture and particulate matter from biogas need to be removed when the biogas produced is utilized to run cogens. One particulate matter is siloxane, a common additive to everyday household items. During anaerobic digestion, silica is converted to silicon dioxide, or sand which overtime will reduce the efficiency, increase operating cost and cause failure for high capital equipment such as engine generators. Varec Biogas offers siloxane removal as part of our gas conditioning/drying system. H2S is a biogas constituent and need to be removed because it is highly corrosive to piping. More importantly, it will degrade the carbon-based filter used for siloxane removal.

DIGESTER GAS TO ENGINE GENERATOR

DIGESTER GAS CLEANING/DRYING EQUIPMENT

GAS CONTROL EQUIPMENT

Biogas is produced within the digester at a rate that creates enough pressure to move gas through the piping system. The gas can be used to run mixing equipment for the sludge. When additional gas is produced and system pressure increases, gas is conveyed for storage at membrane gas holders, or for use in boilers or engine generators. Excess gas produced more than the gas utilization requires is flared.